Launch Vehicle Payload Integration

Launch vehicle payload integration: although it sounds like a mouthful, this process is more straightforward than you might think. This article will walk you through each step of integrating payload space technology into rockets, from the design stage to final testing, to ensure safe and smooth space flight.

What is a Payload?

Simply put, a payload is any object or entity that is being carried by a launch vehicle. Depending on the launch vehicle’s size and mission, a rocket payload can be anything from cargo, spacecrafts, or flight crews to scientific experiments, cameras, communications equipment, sensors, or satellites (check out Skyrora’s Satellite Activity Pack to learn more about the importance and benefits of satellites).

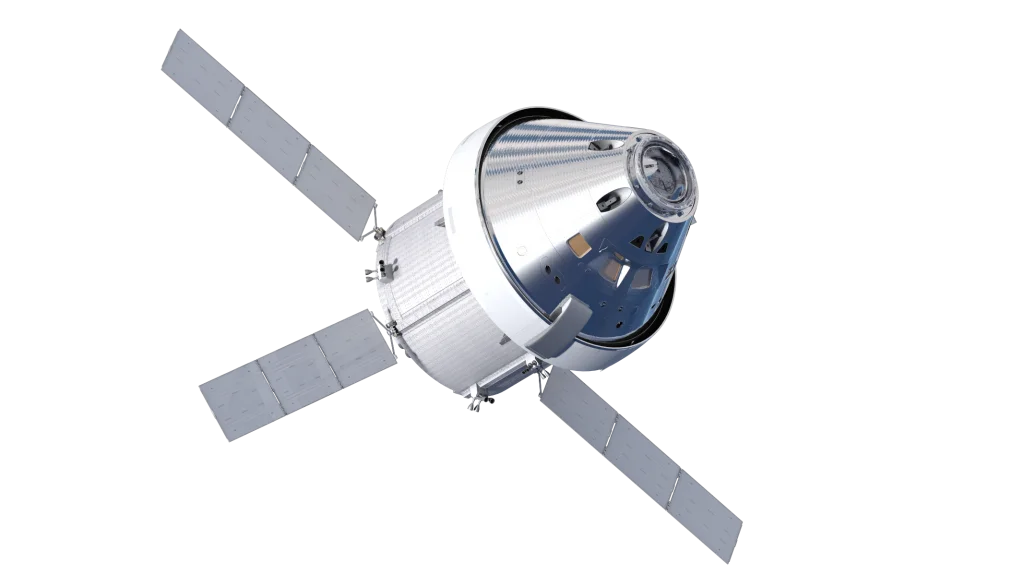

Orion spacecraft | The Orion spacecraft will venture thousan… | Flickr

NASA’s Orion spacecraft is an exploration vehicle that can carry a payload of four astronauts into deep space.

History of Payloads

The earliest payload consisted of fireworks for celebrating holidays. However, during World War II, fireworks were traded out for several thousand pounds of explosives, which were integrated into the German V2 rocket for military purposes. After WWII, several countries integrated nuclear warhead payloads into guided ballistic missiles, and eventually, these missiles were modified to launch space technology such as satellites into space for communication purposes, weather monitoring, spying, planetary exploration, and observation.

Although satellite payloads are highly valuable, the most important rocket payload is a human! During the 1960’s, the US and Soviet Union took special care to ensure military rockets were ‘man-rated’ to ensure the safest space flight possible for astronauts.

On May 5th, 1961, the Soviet Union was finally ready to send a human astronaut as a payload into space. Soviet pilot and cosmonaut Yuri Gagarin made history when he became the first human in outer space aboard the Vostok 1 capsule.

Launch of Vostok-1 | April 12, 1961. Yury Gagarin circled th… | Flickr

Vostok 1 taking off on 12 April, 1961 with cosmonaut Yuri Gagarin aboard.

Did you know?

A few weeks prior to Gagarin’s mission, a prototype of the Vostok 1 capsule called the Vostok 3KA-2 was used in a test launch. The craft completed one low-Earth orbit carrying a life-size dummy named Ivan Ivanovich and a dog named Zvezdochka.

What is Payload Integration?

Due to the intense conditions experienced by a launch vehicle as it leaves Earth’s atmosphere, rocket payloads have the potential to be damaged physically, electronically, or chemically. For example, the extreme acceleration of the launch vehicle or a sudden change in the magnitude or direction of the launch vehicle’s acceleration could physically disrupt the payload. Similarly, the payload’s electronic or chemical makeup could be severely disrupted by extreme temperatures, rapid changes in temperature or pressure, contact with fast moving air streams, or radiation exposure.

To prepare for as many unfavourable launch scenarios as possible, all payloads must undergo a series of tests simulating a variety of launch environments. Once these tests have been completed, the rocket is ready for payload integration, or the installation of the payload into the payload fairing. The payload fairing, or the rocket’s nose cone, is used to protect payloads from the impacts of dynamic pressure and aerodynamic heating as the rocket leaves the earth’s atmosphere.

Atlas V Payload Fairing for Juno | Paulo O | Flickr

The payload fairing of the Atlas V rocket, which carried the Juno spacecraft toward Jupiter in 2011.

Let’s dive into the specific aspects of the payload integration process to better understand how payloads are prepared for launches

Payload Design

Here are some questions designers may consider in the payload design stage:

-

How big can the payload be?

-

How heavy can the payload be?

-

What shape can the payload be?

-

What job does the payload have once it reaches space?

Think of a rocket as a delivery truck: the bigger the truck is, the more boxes it can carry. Therefore, the bigger the rocket, the bigger the payload.

However, in order for a rocket to launch successfully, the upward thrust of the rocket must be greater than the combined weight of the rocket’s payload, propellant, and structure (for more information on thrust, check out Skyrora’s video on how rockets fly). Additionally, the payload must be small enough to fit within the payload fairing.

This means that during the design stage of the payload integration process, designers must solve the tricky puzzle of making the rocket payload as light and small as possible but strong enough to handle the forces of rapid acceleration through the atmosphere.

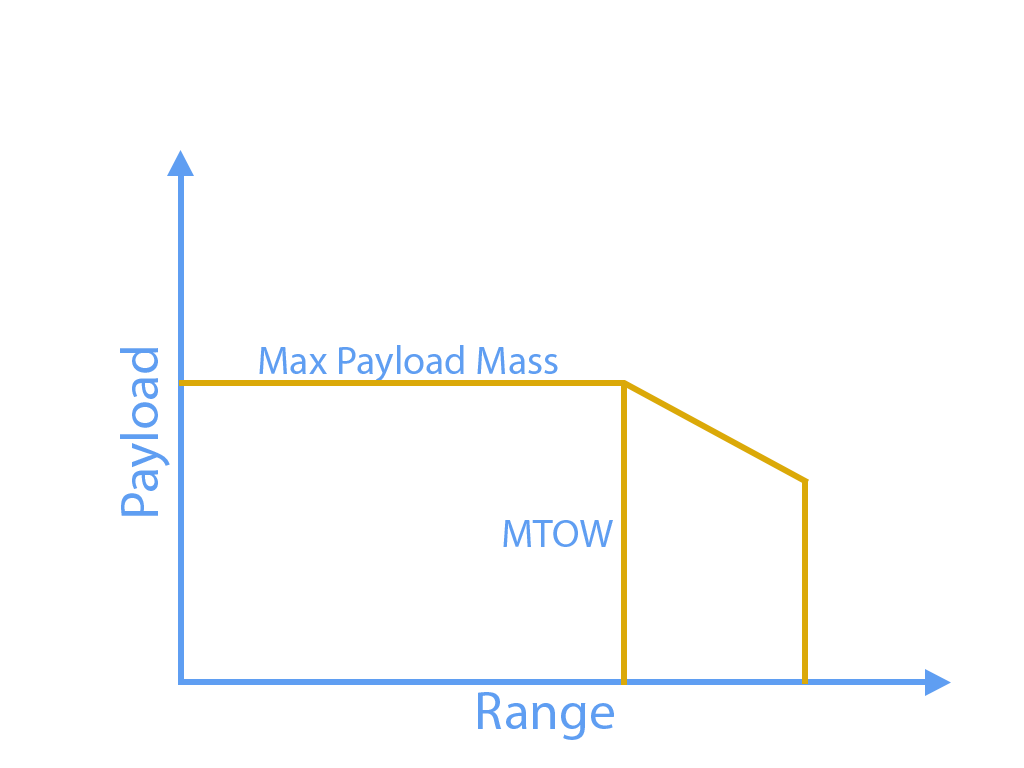

This trade-off between the rocket’s launch capability and the weight of the payload can be represented with this ‘elbow chart.’

-

The top horizontal line represents the maximum payload capacity that the launch vehicle can support.

-

The vertical line represents the point at which the launch vehicle weight, maximum payload capacity, and required amount of fuel reaches the maximum take-off weight (MTOW) of the aircraft. If the range, or distance of the journey to space, is increased beyond this point, then the payload capacity must be sacrificed to accommodate additional fuel.

What Happens If You Exceed Payload Capacity?

If the rocket exceeds its determined payload capacity, the launch vehicle will most likely lose balance and divert from its original trajectory, causing it to go off course and crash. This is why payload integration is of the utmost importance to the overall safety of the launch vehicle.

Payload Testing

After the design stage, several tests are typically conducted during payload integration to ensure the launch vehicle is prepared for a diversity of environments during spaceflight. Here’s a few tests the payload may undergo to become launch-ready.

Vibration Testing

During vibration testing, the payload is placed onto shake tables simulating rocket vibrations and shaken significantly to ensure it can survive the entirety of the launch. The payload is also exposed to powerful speakers that simulate sound waves created by the rocket.

GOES-R SUVI Undergoes Vibration Testing | The GOES-R Solar U… | Flickr

The GOES-R Solar Ultraviolet Imager (SUVI) instrument underwent vibration testing at Lockheed Martin Advanced Technology Center in 2013.

Thermal Vacuum Testing

Thermal vacuum tests are conducted to see if the payload will function properly when it reaches space. Since components behave differently in environments where no air is present, thermal testing in a vacuum can test whether the payload will survive and function in the extreme temperatures of space. During these tests, the payload will increase in temperature by hundreds of degrees to simulate sun exposure and decrease in temperature by hundreds of degrees to simulate the uniquely cold atmosphere of black space.

GOES-R SUVI Undergoes Vibration Testing | The GOES-R Solar U… | Flickr

The GOES-R Solar Ultraviolet Imager (SUVI) instrument underwent vibration testing at Lockheed Martin Advanced Technology Center in 2013.

Spin Balance Testing

A payload must be balanced within its launch vehicle so that the vehicle will remain straight during spaceflight. Therefore, spin balance tests involve placing the payload on a spinning platform and using special sensors to indicate where weight must be added or taken away to ensure a balanced launch vehicle. During these tests, a cylindrical container covers the payload to prevent external air interference.

LADEE Spin Test | During preparations for NASA’s Lunar Atmos… | Flickr

A spin balance test was conducted on NASA’s Lunar Atmosphere and Dust Environment Explorer prior to launch in 2013.

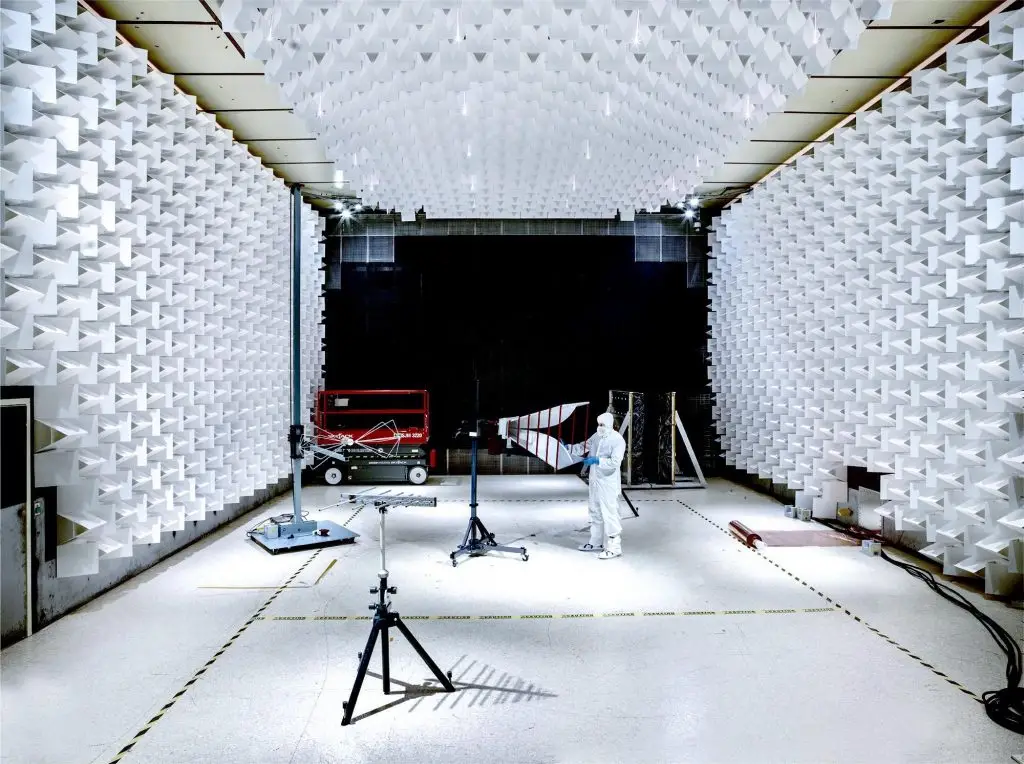

Electromagnetic Interference Testing (EMI)

EMI tests are conducted to ensure the payload does not generate radio signals at the wrong frequencies, which can be problematic for other payloads, rockets, or satellites. EMI tests can also test if the payload is sensitive to any radio signals. These tests occur within a special facility featuring cone structures on the walls that are used to absorb radio signals

Testing with Radio Waves | Stepping inside NASA’s Electromag… | Flickr

EMI testing was conducted on the Integrated Science Instrument Module (ISIM), the science payload of the James Webb Space Telescope, in 2015.

Human Rating Certification

To ensure rockets carrying astronauts are as safe as possible, rockets must receive a ‘human rating certification’ before conducting a launch. There is no universal list of human rating requirements, but NASA’s human rating system requires all launch vehicles to be tolerant of failure and protect the crew even if an unrecoverable failure occurs. Astronauts are also required to have some control over the vehicle at all times.

These requirements were made significantly stricter following the Challenger accident in 1986 that killed seven crew members and the Columbia accident in 2003 that also killed seven crew members. Generally, vehicles carrying humans undergo significantly more testing prior to the launch than automated space crafts.

Did you know?

Astronaut Ellison Onizuka brought a soccer ball used by his daughter’s high school team aboard the Challenger. Somehow, the soccer ball survived the explosion intact and went to space 31 years later with astronaut Shane Kimbrough in honour of the crew.

Testing with Radio Waves | Stepping inside NASA’s Electromag… | Flickr

NASA’s Challenger space shuttle lifted off in 1986 with a crew of seven astronauts.

Final Rocket Payload Integration

Once designs are agreed upon and all payload tests are conducted, the payload is finally ready to be integrated into the payload deck. This involves bolting the payload to the carrier and mounting the entire payload system onto the top of the rocket.

Clearly, the payload integration process is a thorough but necessary one to ensure payloads reach space safely and with little to no disruptions.

Learn More About Rocket Payload Integration

Still curious about the rocket payload integration process? To learn more about the payload system and how it interacts with other systems in a launch vehicle, check out Science ABC’s video on how rockets work. If you are considering a career related to payload integration after reading this article, take a look at Flying Mag’s feature article on how to become a payload integration specialist. Finally, to see the payload integration process in action, watch Space Dynamics Laboratory’s time-lapse video featuring the final payload integration stage for NASA’s Ionospheric Connection Explorer satellite.

Bibliography

Britannica. (2021). How a launch vehicle works. Available: https://www.britannica.com/technology/launch-vehicle/How-a-launch-vehicle-works. Last accessed 01 September 2021.

Chakka, S., Chotai, P., Gurung, K. and Kim, J.. (2021a). How rockets work. Available: http://itsjustrocketscience.weebly.com/how-rockets-work.html. Last accessed 01 September 2021.

Chakka, S., Chotai, P., Gurung, K. and Kim, J.. (2021b). The basic structure of a rocket. Available: http://itsjustrocketscience.weebly.com/the-basic-structure-of-a-rocket.html. Last accessed 01 September 2021.

Edwards, A. (2020). Facts you never knew about the Challenger shuttle disaster. Available: https://www.ranker.com/list/challenger-explosion-facts/aaron-edwards. Last accessed 01 September 2021.

Everyday Astronaut (2017). Rockets and payloads: A beginners guide to rocket vocabulary. 15 April. Available: https://www.youtube.com/watch?v=52uikGLvKqA. Last accessed 01 September 2021.

Foge. (2014). Payload Integration. Available: http://foge.org/wp-content/uploads/2014/06/Payload-Integration-Slides.pdf. Last accessed 01 September 2021.

NASA. (2021). Payload systems. Available: https://www.grc.nasa.gov/WWW/k-12/rocket/payload.html. Last accessed 01 September 2021.

NASA Video. (2016). Payloads. 16 February. Available: https://www.youtube.com/watch?v=20OslSEoWG4. Last accessed 01 September 2021.

Schupak, A. . (2011). 6 surprising facts about the first manned space mission. Available: https://www.youtube.com/watch?v=52uikGLvKqA. Last accessed 01 September 2021.