Ecosene and Waste Plastics

What is Ecosene?

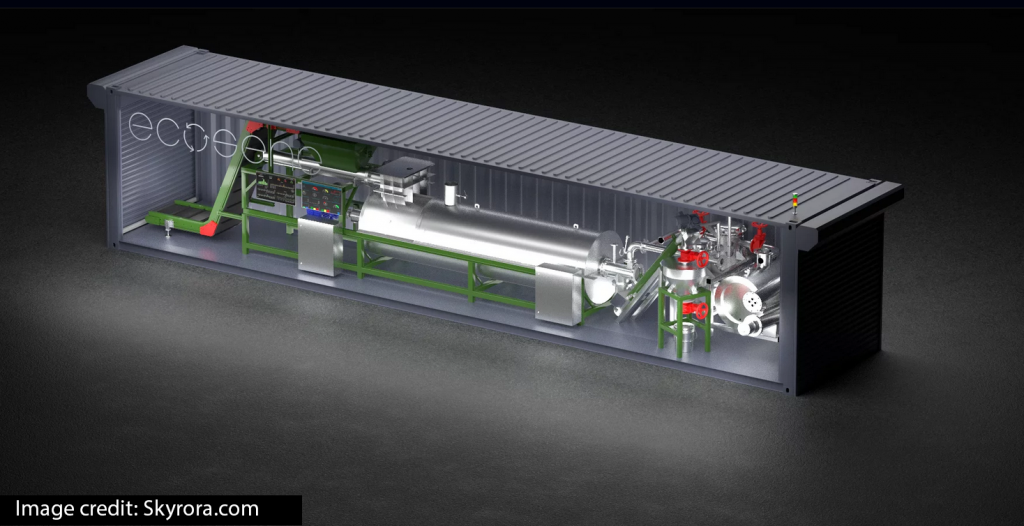

Ecosene is a proprietary IP-owned product of Skyrora, with which plastic waste is converted into high-grade kerosene fuel for use by the aviation and aerospace industries. It provides several environmental benefits as a replacement for traditional oil-derived fuels, whilst meeting the standards required for a Jet A-1 fuel. With this technology alongside existing innovative products Skyrora can provide a sustainable solution to accessing space for the small satellite market.

Skyrora’s Ecosene rocket fuel technology uses catalytic pyrolysis and hydrotreatment to convert plastics including polypropylene (PP), polyester (PE), and polystyrene (PS), with which polystyrene is found to have the best plastic-to-pyrolysis conversion rate. Polystyrene is currently an unrecyclable plastic, and so 100% of all polystyrene waste must go to landfill. Pyrolysis is a low-temperature thermal degradation process during which this plastic is first converted to a low-grade fuel. During the following refinement stages of production, the low-grade fuel is subject to further processing to ensure the resultant product reaches the standards required to meet the Ministry of Defence Standard 91-91 for Jet A-1 fuel. The process used here for the full life cycle has reduced greenhouse gas emissions, with the CO2 levels produced amounting to approximately 154kg per tonne less than those emitted during the production of traditional oil-derived fuels. The resultant fuel provides an ecological alternative with numerous environmental benefits. With a plant based in Scotland Skyrora could, in theory, bring more than 250 tonnes of waste plastic back into circulation annually. To achieve this would be of great significance.

Ecosene has currently reached Technology Readiness Level 5, meaning the company has proven the feasibility of the pyrolysis process and the product has been validated during testing in its appropriate environment. During this testing with Skyrora’s 3.5kN engine, it was found that the liquid Ecosene fuel not only produces significantly less SO2 emissions during burning compared to propellant systems using other aviation fuels, but it is also more efficient than the fossil fuel equivalent. This innovation meets the needs for a global change in attitude towards fossil fuel consumption and plastic waste but also serves the increasing demand for fuel in the UK, and global, launch vehicle industry. The demand for Ecosene as a kerosene liquid propellant equivalent can be observed with the increase in the number of NewSpace launch companies across the globe, as well as monitoring air traffic statistics. Due to this demand, the UK Government’s Sustainable Aviation Fuels (SAFs) mandate means green fuels such as Ecosene are becoming increasingly talked about. With the nationwide target to decarbonise aviation, Ecosene is making a strong contribution to the UK’s capabilities to deliver net zero and zero emission technologies.

By offering a remedy for single-use plastic waste, Ecosene consequently reduces secondary microplastics production and will lead to positive impact on the Scottish economy by creating new job opportunities. This, with the combination of low carbon emissions and reduced waste in landfill means Skyrora provides an eco-friendly option for satellite customers.

Recycling Waste Plastics

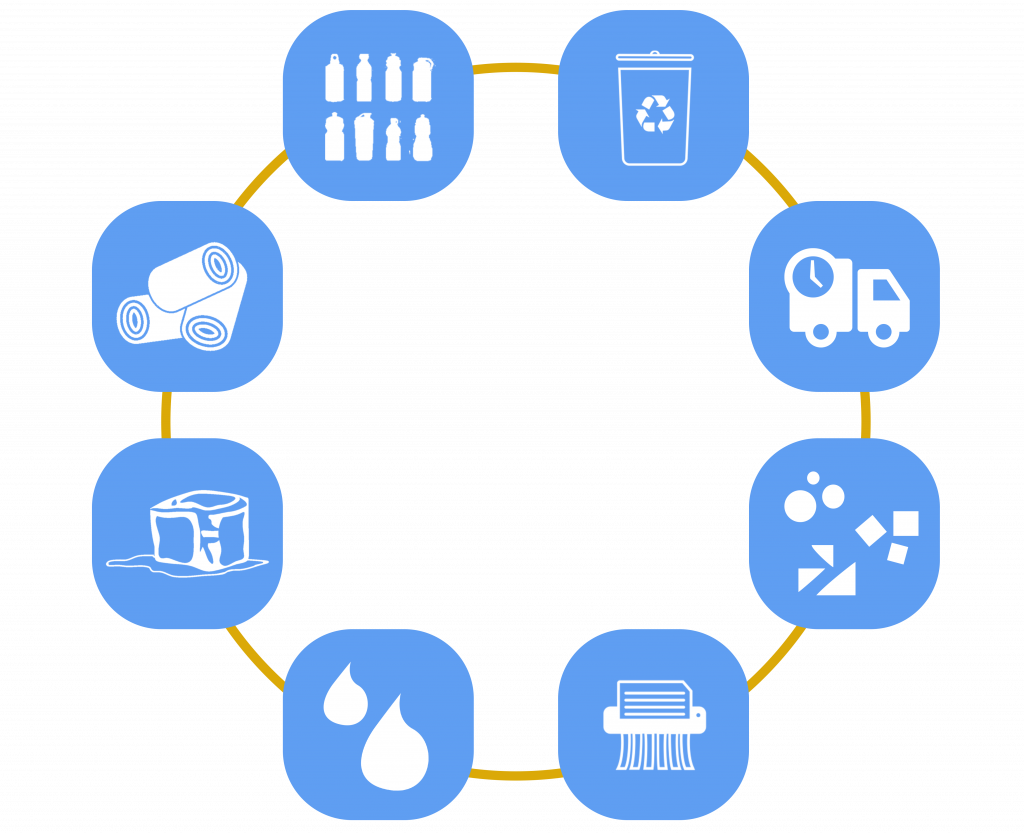

Across the globe, we are using approximately 20 times the amount of plastic we did 50 years ago. A research article discussing ‘The production, use and fate of all plastics ever made’ explains that as of 2015 only 9% of the plastics that have been produced in our world had been recycled. Efforts are being made by councils and commercial businesses offering incentives for companies and individuals to make better efforts to recycle. Once waste has been deposited into bins and collected for processing, the plastics are sorted by polymer type, shredded, washed, melted, pelletised and eventually made into new products. By recycling used products we reduce the need to create new plastics, thus reducing overall waste. Several plastics can currently be recycled in the UK, whilst for other waste plastics we do not yet have the technology to do so.

Large amounts of plastic still go to landfill, and this cannot be sustained. The plastics shipped abroad for recycling or those incinerated immediately raises questions as to just how serious the issue of waste plastic disposal is.

Waste Plastics: The Statistics

The issue of non-recyclable and single-use plastics must be solved if we are to make any contribution towards saving our climate. In 2019, the UK recycling rate was 46.2%, with only a 1.2% increase from the 45% rate in 2018, according to the UK Statistics on Waste from Households. Waste is often exported to be reprocessed and recycled or must simply be buried in landfill - in 2020, 2480 tonnes of plastic packaging waste were calculated to have been disposed of in UK landfill. These offer extremely poor solutions as we work towards a green planet. Alternatively, waste plastics are incinerated, also taking a large step back from reaching global sustainability targets.

Approximately 8Mt of plastic is deposited in the ocean annually, with the research article ‘Plastic Pollution in the World’s Oceans’ stating that ‘more than 5 trillion pieces of plastic are already floating in our oceans’. More than 100,000 marine animals and 1 million seabirds are killed every year by the ingestion of plastics and by 2050 it is predicted that every seabird species on the planet will be eating or will have eaten plastic. Protecting ‘life below water’ is just one of the 17 Sustainable Development Goals (SDGs) set out by the United Nations (UN) as part of the 2030 Agenda for Sustainable Development. Discussed in the article ‘(Micro)plastics and the UN Sustainable Development Goals’: “(Micro)plastic pollution directly or indirectly impacts at least 12 of the UN SGDs.” The 2030 Agenda for Sustainable Development was created in 2015 by the United Nations Member States to tackle climate change and work in partnership to preserve our planet. Whilst reducing plastic waste with Ecosene technology, Skyrora aim to be a sustainable launch provider for the small satellite market which is crucial in meeting these targets set out by the UN. Find out more about ‘Satellite Applications as a Contribution to the UN Sustainable Development Goals’ here.

Skyrora designs and manufactures its products with an environmental conscience in mind, providing the global small satellite market with the essential access to space required to monitor our ever-changing climate. The technologies allowing Skyrora to do this, in addition to Ecosene, include Skyrora XL with its in-orbit manoeuvrability services, the Mobile Launch Complex allowing for decreased manufacturing and set-up costs and logistics, and cutting-edge additive manufacturing technology allowing various composite components to be printed simultaneously, advancing the manufacturing capabilities currently used in the aerospace industry.

Ecosene’s Unique Selling Points

Ecosene sets itself apart from other products on the market, for customers within the aerospace and aviation industry who so heavily rely on large quantities of fossil fuels for propellant systems.

-

Non-recyclable plastics which once would have had no further use and contribute to the major problem of increasing waste in landfill now have a use case with Ecosene fuel for the aviation and aerospace industry. Polystyrene is currently an unrecyclable plastic and so this, as well as polypropylene, is converted to the kerosene replacement fuel in a more sustainable production process.

-

The user, who requires these high-grade aviation and aerospace fuels, now has access to an eco-friendly alternative which reduces CO2 and SO2 emissions over the course of the product's life cycle. For example, in context with the space industry, Ecosene reduces SO2 emissions with every rocket launch compared against other fuel systems. Not only does Ecosene allow for reduced emissions, but customers will contribute to reduced waste in landfill by supporting the production of Ecosene fuel and the re-use of non-recyclable plastics.

-

Environmental goals are met without compromising the quality of the final product. Ecosene meets the standards required for a Jet A-1 fuel, so it maintains the useful characteristics of the traditional kerosene fuel but is also more efficient than its fossil fuel equivalent.

-

Meeting the increased supply and demand emanating from the growing success of the UK space sector, Ecosene’s ability to deliver the product quickly across the UK and Europe is an essential characteristic for customers relying on an efficient rocket propellant within the aerospace and aviation industries.

Visit the Skyrora website to learn more about Ecosene here.

References

1. Department for Environmental Food & Rural Affairs. (2021). UK Statistics on Waste. Available: Last accessed 13th Apr 2022.

2. Department for Transport. (2021). Sustainable Aviation Fuels Mandate. Available: Last accessed 13th Apr 2022.

3. Roland Geyer, Jenna R. Jambeck, Kara Lavender Law . (2017). Production, use, and fate of all plastics ever made. Available: https://www.science.org/doi/pdf/10.1126/sciadv.1700782?download=true. Last accessed 13th Apr 2022.

4. Marcus Eriksen, Laurent C. M. Lebreton, Henry S. Carson, Martin Thiel, Charles J. Moore, Jose C. Borerro, Francois Galgani, Peter G. Ryan, Julia Reisser. (2014). Plastic Pollution in the World’s Oceans: More than 5 Trillion Plastic Pieces Weighing over 250,000 Tons Afloat at Sea. Available: https://journals.plos.org/plosone/article?id=10.1371/journal.pone.0111913. Last accessed 13th Apr 2022.

5. Tony R. Walker. (2021). (Micro)plastics and the UN Sustainable Development Goals. Available: https://www.sciencedirect.com/science/article/pii/S2452223621000535. Last accessed 13th Apr 2022.

6. Recycle Now. (2021). How is plastic recycled?. Available: https://www.recyclenow.com/how-to-recycle/how-is-plastic-recycled. Last accessed 13th Apr 2022.